Custom apparel manufacturing process – 3 minute read

Are you constantly racing against the clock to get your apparel manufactured “on time”?

The highly seasonal fashion industry combined with today’s supply chain disruptions are enough to make the calmest procurement professional go cuckoo.

Follow these 8 critical steps to shave time off your apparel manufacturing process.

Step 1: Prepare

Good preparation takes longer than production.

Are you designing an entirely new apparel line? Sourcing new fabric? Adding embellishments to a top seller? Before approaching a domestic or overseas clothing manufacturer, you’ll need to prepare 5 critical pieces of information for each SKU.

We recommend preparing the following information at least 6 months before you want your product on-shelf.

Step 2: Create Your Tech Pack

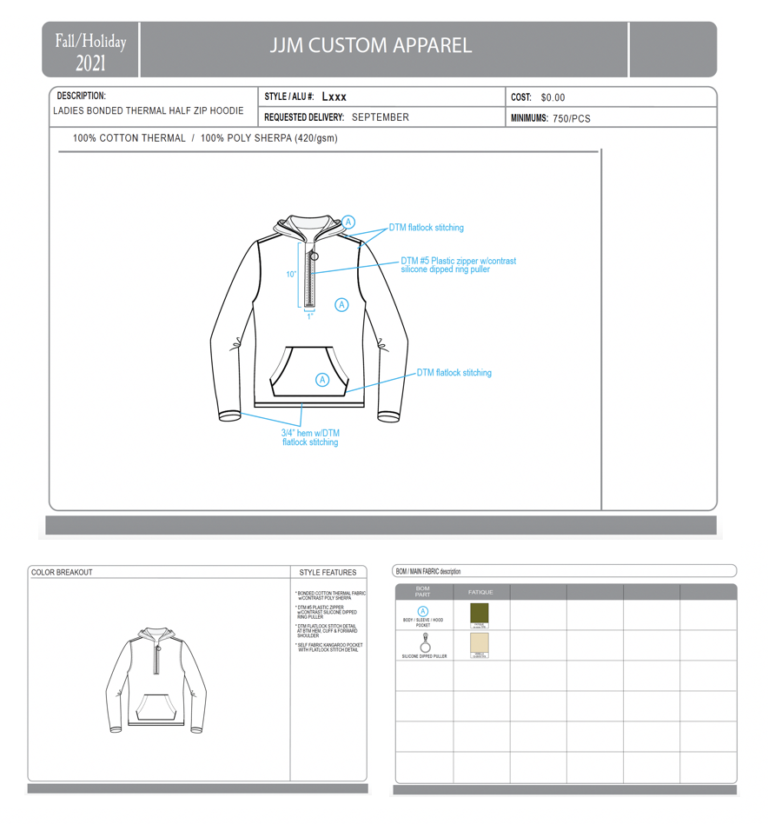

Next you’ll need to create a tech pack. A tech pack contains specific information about your garment design like the size measurements, care label instructions, art-work placement, fabric details, packing instructions, etc. A tech pack should be created with military precision as the factory follows it to the stitch.

JJM works with clients to ensure each tech pack has information itemized properly for an accurate quote and physical sample. A simple tech pack example looks something like this…

Step 3: Choose Your Clothing Manufacturer – Wisely

Choosing the right clothing manufacturer is a critical step that can save (or cost) you time and money.

Do your homework. Get quotes from 2-3 suppliers. Make sure you are comparing apples to apples. For example, do all your quotes include Customs Charges (if applicable), Shipping, Customization, Requested Materials and Physical Samples?

If you’re new to apparel manufacturing “you don’t know what you don’t know”.

We’ve heard horror stories of niche brands literally losing their shirts dealing directly with factories. Poor quality. Long delays. Surprise invoices. Or no product delivered at all. It happens.

JJM takes responsibility for paying the duties, freight, admin and broker fees. There are no extra fees or surprises. We have 30+ year relationships with trusted factories that specialize in specific categories and decorating techniques. We choose the factory with the most experience to manufacture product similar to yours.

Step 4: Get a Physical Prototype

Depending on your product specifications and order size, the sequencing of steps 4, 5 and 6 can vary.

Your physical prototypes may be provided in fit sizes for approval – bypassing a single physical prototype. If your apparel is a new design or a little complicated, one physical prototype with development fabric is advised BEFORE fit samples are done. This allows you to make design tweaks.

Either way, we highly recommend you request a physical prototype BEFORE placing your order. This way, if the supplier’s communications or sample doesn’t meet your expectations, you still have time to find another supplier BEFORE it’s too late (or $$ to turn back the clock).

Step 5: Request Size Fit Samples

You know your customer best. The only way to verify your size specs are “bang on” is to review sizing samples. This also allows your supplier to estimate the fabric yield more accurately. It may seem like a time consuming step. Trust us, it’s not.

JJM has feet on the ground in China, so our Shanghai team saves you time by validating fit sizes, lab dip colors, fabric quantity & quality.

Step 6: Place Your Order

You’ve evaluated a physical sample, you like your supplier’s workmanship and are comfortable with their communications. NOW is the time to place the order.

Typically manufacturers will require 30% down* and the remaining 70% of payment upon shipping.

*payment structures vary based on order size and client relationship

Step 7: Begin Pre-Production

Once you’ve tweaked, tested and approved your physical samples, your manufacturer will order the fabric AND schedule production. If you are a niche brand working directly with a factory, chances are good your order will be relegated to the bottom of the production schedule. Larger brands that provide a steady flow of orders get priority.

JJM has long-time relationships with factories. This gives us leverage. We also have insight into available manufacturing capacity. This maximizes production efficiency and cuts down turnaround times (saving you oodles of time, before production even begins).

Step 8: Start Production

You made it to the final step! But you’re not out of the woods yet. Unfortunately, it’s not unheard of for physical samples to look 100%…but your actual product is not.

With feet on the ground in China AND North America,

- JJM’s Shanghai team inspects factories for workplace and material compliancy. We’ll spot check orders for quality before product is shipped out – saving you time and future trouble.

- JJM’s North American team provides admin support, up-to-date tracking and status reports. We’ll let you know when your product is landing, so you’re ready.

Simplifying the production process is our superpower.

Want to strengthen your apparel supply chain? Partner with us. Our experienced project managers handle product development, sampling, pre-production planning, sourcing, manufacturing and delivery. We’ll make your overseas apparel manufacturing experience easy and stress-free.

Contact Us for a complimentary consultation today!