Custom Apparel Manufacturing - 3 minute read

Keep your suppliers close

Consolidate and Collaborate

It’s not your imagination.

More factors are disrupting

the apparel supply chain NOW than ever. The pandemic has underscored how vulnerable the apparel industry is to

uncontrollable events. Supply chain fallouts from COVID, economic uncertainty, climate change, demographics and geopolitics are

causing apparel executives to re-look at who, how and where their clothing is

manufactured.

How can your apparel supply chain be more resilient? Partner vs. Transact

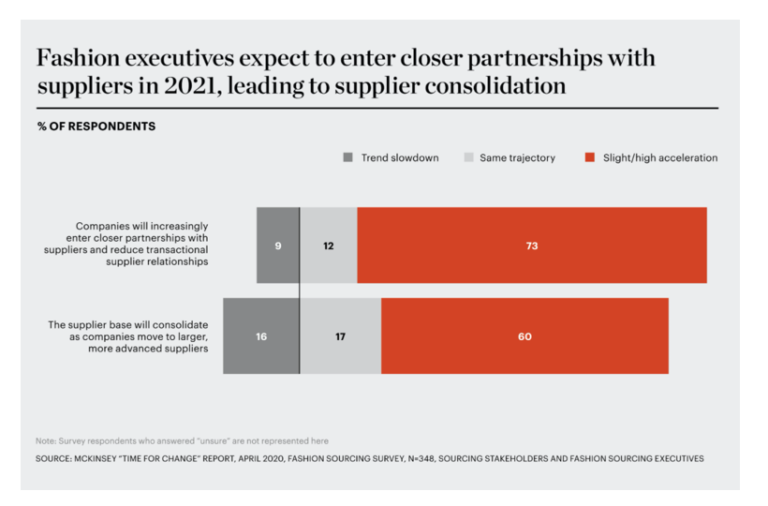

According to McKinsey’s Time for Change, April 2020 Fashion Sourcing Survey, 73% of fashion executives expect to reduce the number of suppliers they purchase from AND enter into more long term relationships in 2021.

Here are 3 reasons why…

1. Strategic Partnerships = More Efficient Processes

Partnering with strategic suppliers vs the lowest cost suppliers has many benefits. Deeper relationships allow for more collaboration which can result in more design expertise, innovative material sourcing and technologies that make processes more efficient.

Since strategic suppliers are vested in your success, they are more likely to embrace new tools AND share the risks. If issues come up, having a strong relationship with suppliers vested in your brand gets issues resolved faster.

Developing strong relationships and collaborating with clients has been JJM’s modus operandi for over thirty years. Clients say this model makes their production process more efficient and budgeting easier.

2. Strategic Partnerships = Fewer Supply Chain Shocks

Over the past ten years, big brands looking for lower-wage, lower-cost operations started moving production to Myanmar, Bangladesh, India, Pakistan and other countries with budding apparel industries. Unfortunately, these developing countries often lack adequate worker protections and are starting to experience the effects of climate change. These factors on top of the COVID-19 pandemic have tested their supply chain resiliency.

There’s a reason why China is the world’s dominant apparel manufacturer accounting for about 29% of clothing sold globally. Chinese factories were able to rebound from shutdowns and get back to production quickly during the pandemic. Their infrastructure, policies and access to materials minimized client exposure and lead times.

Many brands large and small (think H&M) are moving production from developing countries due to supply chain instability.

With Feet on the Ground in China, JJM works with the best factories and frequently audits labour, safety and quality compliance – in person. Performing these stress tests mitigates supply chain risks and ensures social compliance.

Note: Regardless of where your overseas manufacturer is located, you are going to experience longer lead times due to container shortages and shipping congestion in 2021. To avoid critical delays, we recommend clients take these factors into consideration when planning.

3. Strategic Partnerships = Circular Sustainability Initiatives

Transparency and Sustainability have never been more important in your supply chain. Conscious consumers have been raising concerns for decades. What’s changed is the voice and the platform.

Generation Z is driving the sustainability movement. They are the 2nd largest online buying segment, accounting for about 40% of US consumers. By 2026, Gen Z will surpass millennials as the largest consumer segment in the US. Gen Z is also the most ethnically diverse, educated and environmentally conscious cohort ever. According to the Pew Research Center this generation is using online platforms effectively to be heard. Their activism and size is starting to influence older segments’ climate change sentiments and buying decisions.

According to McKinsey’s April 2020 Consumer Sentiment Survey:

- 63% of all consumers consider a brand’s sustainability an important factor in their buying decision

- 67% of all consumers consider the use of sustainable materials a buying factor

Consumer voices will continue pressuring companies to consider the planet and people making their products, not just profits. Brands and B Corp companies like Athleta are building sustainability initiatives into their strategic business models.

Main Message: Long term supplier contracts encourage collaboration which improves innovation, supply chain stability and sustainability.

Additional references

- If you found this 3 minute read helpful, download Business of Fashion and McKinsey & Company’s report for more in-depth research and insights into the global fashion industry in 2021.

- JJM sponsored a May 2021 webinar entitled “From Wear to Wearer. Unfolding Fashion’s Evolution & Future” hosted by The NPD Group. For select slides, click here.